- Home

- Products

- Machine Cleaning Room Cleaning

Loom Travel Cleaner

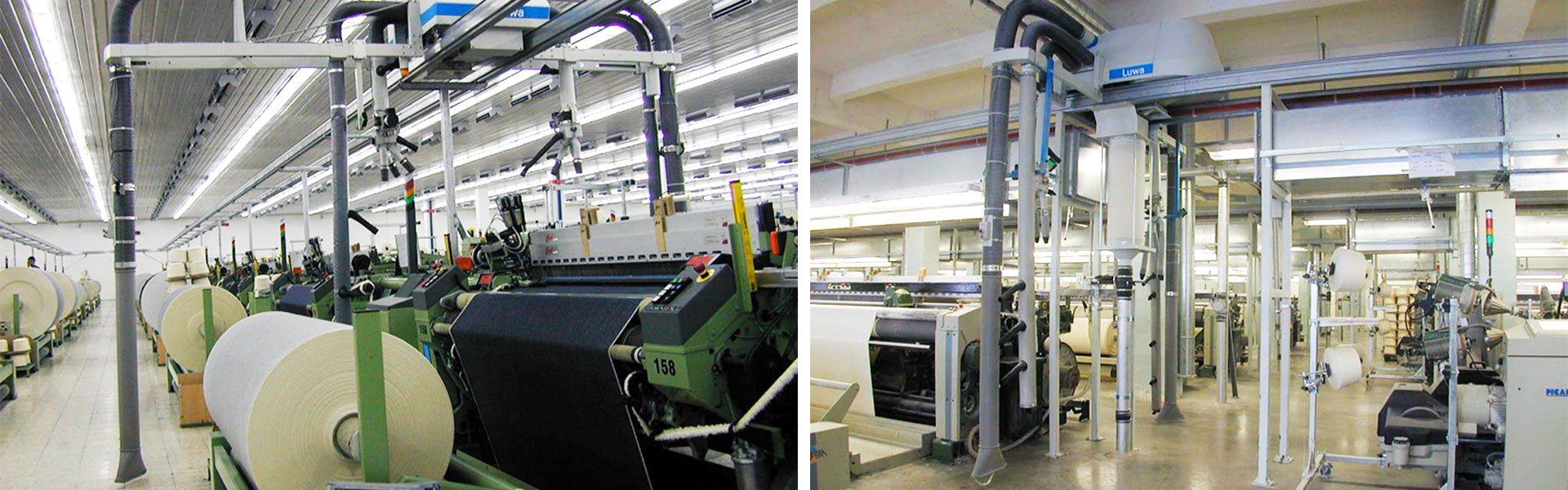

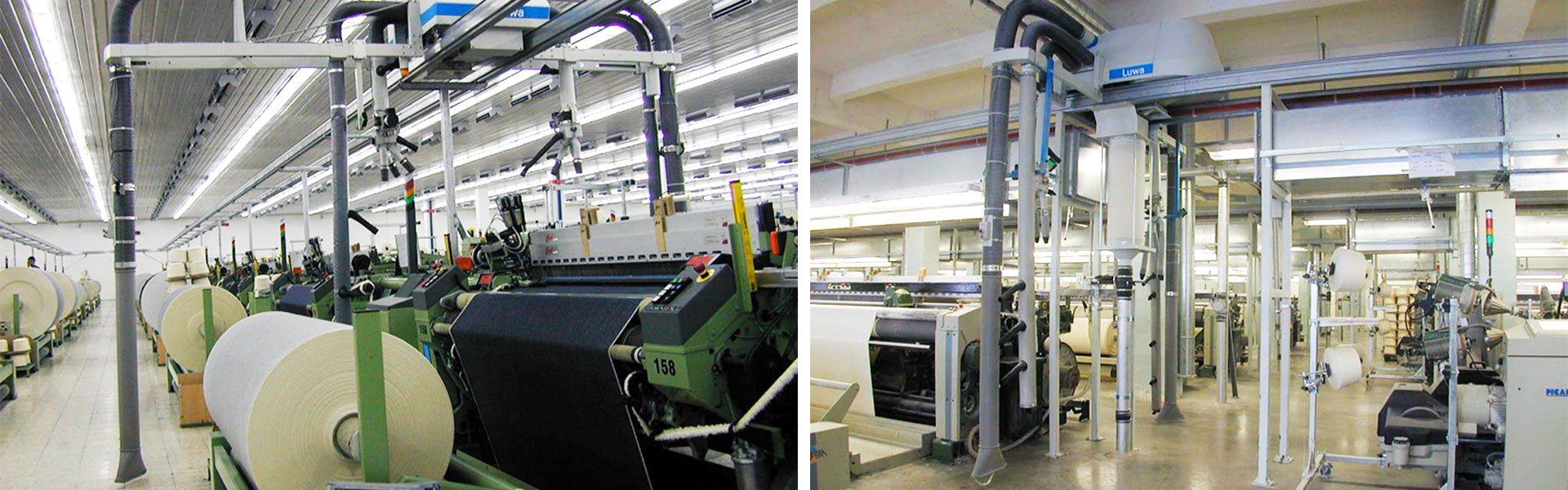

Loom Travel Cleaner (LTC)

Advanced Automatic Cleaning System for Weaving Machines

The Loom Travel Cleaner (LTC) is a state-of-the-art solution designed to enhance the productivity and reliability of weaving machines. This automatic loom cleaning system ensures high efficiency, improves the production environment, and delivers better fabric quality with reduced operational interruptions.

Equipped with oscillating blowing nozzles and separate air supply and exhaust systems, the Loom Travel Cleaner delivers superior cleaning performance, ensuring efficient and reliable maintenance for weaving machines.

Key Features of Loom Travel Cleaner

- Oscillating Blowing Nozzles: Ensure large-surface cleaning of weaving machines, efficiently removing dust and debris even from hard-to-reach areas.

- Separate Air Circuits: Dedicated air supply and exhaust circuits maintain high suction and blowing capacity for optimal cleaning performance.

- Collision and Obstacle Recognition: Integrated infrared sensors detect obstacles, preventing collisions and ensuring safe, uninterrupted operation.

- Two-Track System: Offers unique traveling stability for smooth and efficient movement along weaving machines.

- Automatic Dust Container Emptying: Reduces manual labor by automatically emptying the dust container, promoting a cleaner and safer working environment.

- Customizable Settings: Individually selectable speeds, unloading times, and cleaning programs to meet different operational requirements.

- Modular Configuration: Adaptable design suitable for various weaving machine types and applications.

Benefits of Loom Travel Cleaner

- Best Fabric Quality: Operates without interference from dust and debris, resulting in higher fabric quality and fewer defects.

- Increased Productivity: Minimizes thread breakages and weaving flaws, maintaining continuous production and boosting productivity.

- Reduction in Operating Costs: Efficient design lowers manual intervention, maintenance needs, and downtime, reducing overall operating costs.

- High Degree of Comfort and Safety: Ensures ease of operation with minimal maintenance and promotes a safe, clean working environment.

- Fully Automatic Operation: Autonomous system requiring minimal manual involvement, providing consistent cleaning around the clock.

- Flexible Modular Design: Easily integrated and customized for different weaving machines and production setups.

Applications of Loom Travel Cleaner

- Weaving Mills: Maintains a clean, efficient environment for high-quality textile production.

- Textile Manufacturing Units: Provides consistent cleaning, enhancing productivity and reducing downtime.

- Specialty Fabric Production: Ensures the pristine condition required for delicate and high-value fabrics.

Optional Enhancements

Complement the Loom Travel Cleaner with Luwa's LoomSphere direct air conditioning system, significantly reducing warp breaks and energy consumption.

Contact Luwa Air Engineering

Ready to take your weaving efficiency to the next level? Contact Luwa Air Engineering today to learn more about the Loom Travel Cleaner and how it can benefit your textile operations.

Our team of experts is here to assist you in choosing the best solution for your specific needs.