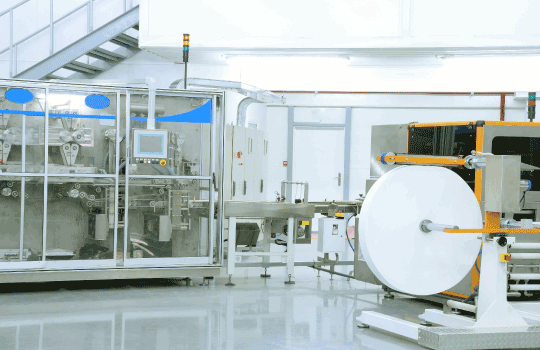

Nonwoven is emerging as a great alternative to textiles due to its versatile properties and single use requirements. According to a report by ReportLinker, the Nonwoven market is projected to reach an impressive $73.13 billion by 2027, driven by a steady compound annual growth rate (CAGR) of 7.5%. From absorbent hygiene products like baby diapers, feminine hygiene products to face masks, nonwoven materials are an ever-present part of our world. Behind the scenes, Total Air Engineering ensures the right ambient conditions and most efficient operations to manufacture these essential materials.

The production of high-performance nonwovens involves a complex interaction of materials, machinery and apt environmental conditions. These processes efficiencies rely heavily on room climate and process air control to deliver the products we depend on. This is where air engineering plays a vital role, in understanding the process requirements and always ensuring the right conditions for efficient production and exceptional product quality.

Let's dig into the characteristics of Air Engineering technology in nonwovens production and find out how it plays a key role in creating an ideal environment for these processes. To deeply appreciate its significance, we must first identify some of the common challenges that manufacturers face.

Humidity control is a delicate balance that can make or break the entire process. Imagine a production space where synthetic fibers are being transformed into nonwoven materials; maintaining the correct humidity level is one of the key essential tasks for smooth and most efficient machine operation.

Let’s examine the science behind humidity in nonwovens. Moisture in the air reduces electrostatic charges, especially on synthetic fibers, which can have a negative impact on the production process. However, too much humidity can also lead to lapping and reduce the effectiveness of disentangling and alignment of fibers. It also directly influences properties such as breaking forces and elongation.

The optimum humidity levels can vary depending on the specific raw materials used and their mix. Higher relative humidity levels, for instance, can result in lower room temperatures due to evaporative cooling. Achieving the perfect balance is a challenge, and this is where air engineering solutions come into play.

Not all industrial processes are equally sensitive to temperature fluctuations, but for many, maintaining a constant temperature is key for both process and the operator. Most nonwoven raw materials are hydrophilic, meaning they tend to absorb moisture from the environment, and this absorption capacity changes with temperature.

A stable temperature not only reduces variation in product quality but also has several other positive effects.

Fluctuations in room temperature can be minimized by employing refrigerant cooling instead of evaporative cooling, especially during hot summer months and monsoon seasons. This ensures that the nonwoven production process runs smoothly, without disruptions caused by temperature variations.

In any nonwoven process, handling waste is an inevitable part, and efficiently handling this waste is crucial. Most nonwoven process machines are equipped with integrated suction points that can be directly connected to a fiber depositing system. This fiber separation and dust filtration system must be carefully designed to handle the required air volume and the amount of waste generated.

The challenge here lies in the diversity of raw fibers used in the plant. Depending on the materials, appropriate fiber separators may need to be installed to separate different materials from each other. Modern fiber depositing plants are integrated with baling press systems and briquetters to efficiently handle the waste & dust collected from various sources in the nonwoven process and converting lines.

The dependency on the fiber depositing system is so essential that any standstill of either the fiber depositing plant or the baling system can lead to an immediate shutdown of the entire production machine. This underscores the critical role of efficient machine exhaust and waste management in nonwoven production.

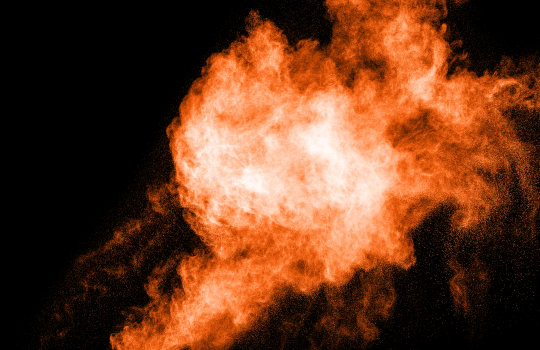

Some of the nonwoven process has combustible material and this can burn rapidly when in a finely divided form. If such a dust is suspended in the air in the right concentration, under certain conditions, it can become explosible. Even materials that do not burn in larger pieces (such as aluminum or iron), given the proper conditions, can be explosible in the form of dust.

The force from such an explosion can cause employee deaths, injuries, and destruction of entire buildings.

Also, when a filtration system collects this combustible dust in the appropriate dust collectors, it becomes even more crucial to handle it and to have proper prescribed explosion venting and isolation devices on the dust collectors.

Nonwovens production facilities must be a cleanroom of sorts. To achieve this, many nonwoven processes are maintained at a constant overpressure, ensuring that air flows out of the production area and prevents external dust or foreign materials from entering.

Depending on the quality of outside air, fresh air filters and supply air filters are required to maintain the desired level of cleanliness. Local regulations may set Permissible Exposure Limits (PEL) to protect nonwoven workers from byssinosis, a respiratory condition caused by inhaling process aerosol dust. Therefore, maintaining sufficient air changes throughout the process is crucial to dilute dust levels and maintain a clean production environment.

Now that we've identified these critical points, it's evident that proper air engineering solutions are absolute necessities in any nonwovens production. Air Engineering optimizes humidity, temperature, machine exhaust, and room cleanliness, ensuring that the production process flows seamlessly, and the end products meet the highest quality standards.

Air Engineering Solutions: Creating The Right Conditions At All Times

To address these challenges effectively and elevate nonwoven production to new heights, manufacturers rely on air engineering solutions. These essential systems are designed to create and maintain the ideal conditions for nonwoven processes. The air engineering solutions are tailored to the unique challenges faced by nonwoven manufacturers, offering precise control over critical factors like humidity, temperature, machine exhaust, and room cleanliness.

As we conclude this exploration of air engineering in nonwoven production, stay tuned for the next instalment in our series. We will dive deeper into the innovative solutions offered by Luwa, a global leader in Air Engineering, and discover how their cutting-edge technologies are shaping the future of nonwoven manufacturing. Join us as we continue to uncover the hidden heroes of the industry and their remarkable impact on our world.