In 2022, Asia-Pacific emerged as the largest player in the market, and its growth remains robust. It is poised to be the fastest-growing region in the forecast period, setting a noteworthy pace for innovation and progress in this dynamic industry. Across the globe, spanning Asia-Pacific, Western Europe, Eastern Europe, North America, South America, and the Middle East and Africa, the nonwoven market presents a growth opportunity. However, in this intricate , precision and efficiency serve as the essential threads that weave it all together.

Luwa is a significant contributor in the pursuit of optimal conditions in these markets. High-performance nonwovens processes demand nothing short of perfection, and that's precisely where Luwa's Air Engineering Solutions shine.

From the meticulous design of filtration systems to the cutting-edge precision of advanced digital solutions, Luwa offers a comprehensive suite of products and solutions crafted with precision. These products and solutions ensure that the production process flows seamlessly. In the ever-evolving landscape of nonwovens manufacturing, Luwa is the clear choice for precision and efficiency with its exceptional product offerings.

TexFog - Maintaining the right level of humidity is crucial in nonwovens manufacturing to ensure product quality and production efficiency. Luwa's TexFog is a high-pressure humidification plant designed specifically for nonwovens and textile industries. This system allows precise control of humidity levels in the air flow through partial saturation via pumps, all controlled by frequency inverters. It excels in both efficiency and hygiene, making it a preferred choice for industries such as nonwovens, food, hygiene products, and textiles. Here are some of its key benefits and functions:

TexPac - For nonwoven applications, the compact TexPac centralized air-handling system is a versatile solution. It is constructed from profiled galvanized sheet steel elements, offering high stability and excellent acoustic insulation. TexPac is designed for installation inside buildings and can be customized to meet specific performance and space requirements. Here are its key features and advantages:

Uniluwa - Uniluwa is a stand-alone unit designed for small air volumes and high heat loads, making it a perfect addition to Luwa's Compact Filter Unit (CFU) when space is limited. It is also well-suited for temporary applications. Uniluwa features a modular, inline layout with a self-supporting double panel construction housing and the efficient TexFog high-pressure humidifier. Some of the key benefits and options of Uniluwa include:

Luwa offers several innovative solutions for managing machine exhaust in nonwovens manufacturing. Let us explore these products:

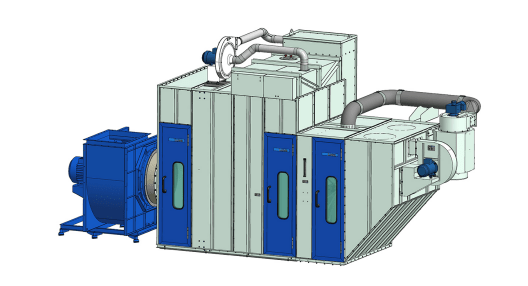

Compact Filter Unit (CFU-MCV) - The CFU-MCV is a compact filter unit that integrates the Multi Cell Filter into a galvanized sheet steel housing. This plug-and-play solution is designed for easy installation on a finished floor, without the need for extensive construction work. Key features and advantages of CFU-MCV include:

Rotary Drum Filter (LDF) - The rotary drum filter is designed for fine dust filtration in exhaust air with a high concentration of dust and fibers, commonly found in spinning and weaving mills. It ensures compliance with regulations for exhaust air quality and offers economic advantages where sufficient space is available. Key characteristics and advantages of LDF include:

Multi Cell Filter (MCV) - The Multi Cell filter is designed to filter return air contaminated with dust and fibers. Its distinctive design with bottom entry filter cells prevents clogging with fibrous material. Key features and advantages of MCV include:

Rotary Pleated Belt Filter (RPB) - Luwa's Rotary Pleated Belt Filter is a revolutionary design that combines high-capacity pleated media with high-efficiency suction cleaning. This results in a high-efficiency self-cleaning filter that offers more capacity for its size than any other filter in the market. Some key features and benefits of RPB include:

Circulaire® Fan - Luwa's Circulaire® Fan is an efficient cleaning fan designed for nonwovens and industrial applications. It plays a critical role in maintaining a clean and dust-free environment, especially in areas with exposed ceiling constructions. Here are the key features and benefits of the Circulaire® Fan:

Luwa's extensive array of air engineering solutions has transformed nonwovens manufacturing to be most effective and efficient. With many years of knowledge of the industry's intricate technical prerequisites and localized demands, Luwa retains its position as a global pacesetter in air engineering sector. Be its innovative filtration systems, adaptable air handling plants, efficient waste management solutions, or state-of-the-art digital solutions, Luwa's products stand for efficiency, sustainability, and innovation in the nonwovens manufacturing sector.

Luwa's technology is as an essential component for nonwovens manufacturers dedicated to achieving excellence in their operational processes. As the industry undergoes future transformations, Luwa is committed to continuously achieving the highest quality, efficiency and environmental compatibility in the production of nonwovens.

If you are intrigued, kindly reach out to us at [email protected], and our dedicated sales team will be delighted to connect with you. Your journey towards a brighter, more sustainable future in nonwoven manufacturing begins with Luwa.